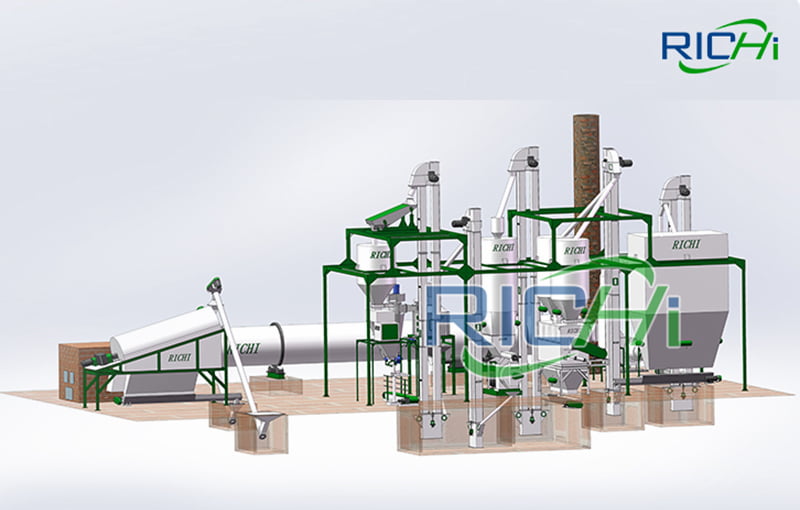

The wood pellet manufacturing plant is specifically made by our designers. It consists of the whole procedure of biomass fragment production, such as chipping, drying, squashing, humidity regulation, granulation, air conditioning, screening, packaging, and so on, which can be adjusted according to the actual situation.

The related cases are:

Basic material are suitable for plant fibers such as logs, branches, sawdust, rice husks, and so on. The materials are communicated by belt conveyor and afterwards sent to timber hammer mill. The majority of the smashed products are straight communicated by screw conveyor. Great powder as well as excess gas are gathered by cyclone separator. The fine powder is discharged by the air lock, and the excess gas is discharged by the generated draft fan. The dirt collector can collect great dirt during the squashing process.

It goes into the drum clothes dryer, and also the materials will be blended with warm air. The dried out products shall be gathered by the cyclone separator as well as after that come out from the base of the air lock.

The product gets in the wood pellet machine through the screw conveyor. The products with suitable humidity are sent to the pelletizing chamber. After the granulation process, the material comes to be cylindrical particles with a size of 2-12mm.

After that these pellets directly get in the colder, drying out the pellets to listed below 10%, and also cooling them to regular temperature. Afterwards, the powder will certainly travel through the rotary classification screener, which can screen out unqualified materials and also powder them once again. The screened pellets are loaded by an automated weighing device and then sealed by an automatic stitching machine.

Knowing the particular manufacturing procedure, and afterwards how to select the devices of a wood pellet plant?

We must know that the complete set of timber pellet plants is not only timber pellet production machine, however likewise other various pretreatment devices according to the kind of raw materials and humidity. If the raw product is twigs, it requires to be squashed into timber chips much less than 5mm by a crusher. There is no requirement to crush or break it if the raw product is sawdust.

Look at the moisture material of raw materials, that is, humidity. It can directly go into the granulated machine bits if the moisture content of the raw product is 15%-20%. If it is more than 20%, it has to be dried out by a dryer to 15-20% prior to granulation.

Organize the design according to the specific needs of customers. The degree of automation, hoping to save labor, high automation intensity, requires automatic air conditioning, automatic packaging and also automated feeding.

In a word, the full collection of equipment for wood pellet plant to buy is not a taken care of setting, as well as can be customized according to various customer needs.

As a brand-new type of eco-friendly fuel, wood pellet items have lots of benefits, such as high calorific value, reduced exhausts, large bit proportion after molding, little quantity, and combustion resistance. Timber chips are widely used in various fields as a result of their high density, high sanitation, and really suitable for transport as well as storage. Timber chips are extensively utilized in different fields due to their high density, high tidiness, and also really appropriate for transportation as well as storage space. We typically heat our residences, and the pellet gas made use of in the residential cooktops are all from tiny sawdust pellet factories. If timber bits are generated on a large scale, they can be used in small central heating boilers, industrial central heating boilers, power plants, etc.

The use of wood pellet fuel generated by wood pellet plant, a different power resource and also an eco-friendly gas, can make a substantial contribution to "greenhouse gas exhaust decrease", and also at the same time can significantly reduce energy usage. Compared with fossil fuels, it can save more than 50% of energy typically.

It is reported that timber pellet fuel is an ecological pleasant business fuel product that is made by drying, pressure creating as well as cooling down wood by-products created after logging or timber chips generated after wood processing. It is utilized as central heating boiler fuel and also can replace chemical fuels such as light oil. In addition, compared with chemical gas, wood pellet gas is likewise a brand-new renewable energy with excellent economic performance, which has been widely popularized in developed nations such as North America as well as Europe. It can be stated that it is one of the future alternative energies.

For financiers or entrepreneurs, what tools is needed to develop a wood pellet plant. This problem mostly varies according to the output and also raw products. How much is a wood pellet plant?

Look at the raw products. Due to the fact that of the various raw materials, some need drying machines, crushers, dust enthusiasts, feeding makers, as well as other equipment and equipment.

Consequently, if you truly want to make use of a set of equipment, you ought to first understand what your raw materials are, how much you need for a day's result, whether it is to be dried on the site or dried out by device. After thinking about all elements, you can furnish on your own with a wood pellet plant devices that is most appropriate for you.

More information is on the website:

Or you can contact:

Whatsapp: +86 18574103366

Email: enquiry@richipelletmill.com