In the intricate landscape of materials science, the quest for absolute purity is a relentless pursuit, especially for rare earth oxides, whose applications span from catalysis to cutting-edge technologies. "Ultra-high purity" rare earth oxides, materials refined to achieve minimal contamination levels often exceeding 99.99% purity, stand at the forefront of this pursuit. This article explores the essence of ultra-high purity rare earth oxides, the meticulous process required to attain such purity, and their indispensable role in catalysis, highlighting why such extraordinary purity is not a luxury but a necessity in the modern technological domain.

Defining Ultra-High Purity

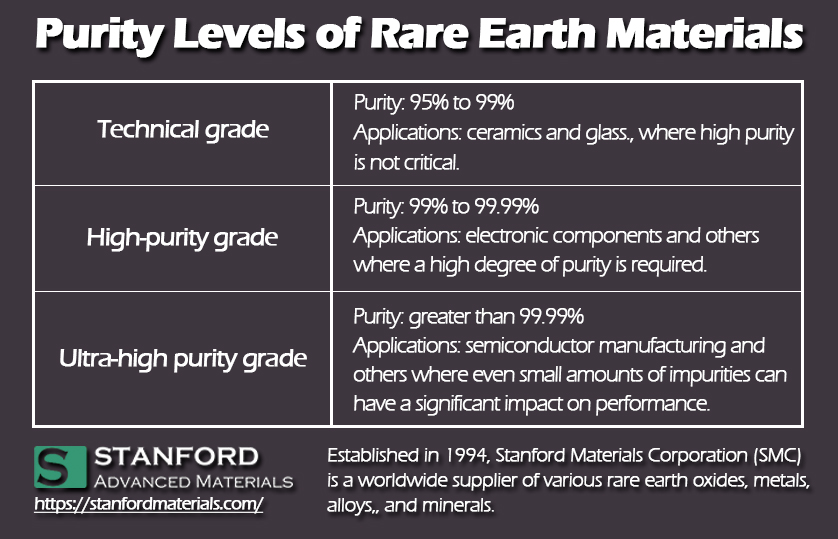

The term "ultra-high purity" connotes a degree of refinement where rare earth oxides are processed to remove virtually all unwanted metallic and non-metallic impurities. Achieving purity levels exceeding 99.99% is critical in applications where the slightest presence of impurities can dramatically impact the material's performance. The distinction of ultra-high purity underscores the material's superior quality and its ability to meet the stringent requirements of advanced applications, particularly in catalysis, where the precision and efficiency of chemical reactions are paramount.

The Journey to Ultra-High Purity

Attaining ultra-high purity in rare earth oxides is a feat of modern chemistry and engineering, involving sophisticated separation techniques such as solvent extraction, ion exchange, and chromatography. Each step in the purification process is meticulously designed to target and remove specific impurities without compromising the integrity of the rare earth oxides. This precision is essential, as the unique properties of rare earth elements - from their magnetic and optical characteristics to their reactivity - can be significantly influenced by the presence of even trace amounts of contaminants.

A Catalyst for Innovation

In the world of catalysis, ultra-high purity rare earth oxides are prized for their ability to serve as highly efficient and selective active sites for chemical reactions. The purity of these materials ensures high activity, facilitating reactions with remarkable precision and yielding products with minimal byproducts. This level of performance is crucial for a wide range of industrial applications, from the synthesis of chemicals and pharmaceuticals to the development of environmentally friendly technologies for pollutant removal.

The impact of impurities on catalytic processes cannot be overstated; even trace contaminants can poison catalysts, reducing their activity and longevity. Thus, the ultra-high purity of rare earth oxides not only enhances the efficiency and selectivity of catalytic reactions but also contributes to the stability and durability of the catalytic system. This is particularly vital in processes demanding long-term consistency and reliability, underscoring the value of ultra-high purity materials in sustaining technological and environmental progress.

Read more: Ultra-High Purity Rare Earth Oxides in Ionic Adsorption

The Future of Ultra-High Purity Rare Earth Oxides

As technology continues to advance, the demand for ultra-high purity rare earth oxides is expected to rise, driven by their critical role in catalysis and other high-tech applications. The ongoing research dedicated to enhancing the mechanical and chemical properties of these materials, coupled with innovations in purification techniques, promises to broaden their applicability. From enabling more efficient chemical manufacturing processes to driving the development of sustainable environmental solutions, ultra-high purity rare earth oxides are poised to play a pivotal role in the next wave of scientific and technological breakthroughs.

In conclusion, ultra-high purity rare earth oxides represent the zenith of material refinement, a testament to the lengths to which science and engineering have gone to meet the ever-increasing demands of technology. Their unparalleled purity, achieved through sophisticated processes, is essential for applications where precision is crucial, particularly in catalysis. As we look to the future, the significance of these materials is only set to increase, highlighting their indispensable role in shaping a world where performance and sustainability are inextricably linked.

In this journey of exploration and innovation, the collaboration between researchers, industry professionals, and suppliers like Stanford Materials Corporation (SMC) is crucial. SMC's commitment to providing high-quality rare earth materials supports the ongoing development of cutting-edge applications, ensuring that the catalytic potential of rare earth oxides is fully realized. The future of catalysis, powered by ultra-high purity rare earth oxides, holds bright prospects for advancements in technology and sustainability, marking a new era in the application of these remarkable materials.