Computer software options for prefabrication and MEP Global Engineering - Top MEP Design and BIM Company in building abound. This short article tries to enable establish the right healthy, with regards to the style of prefabrication expected.

The prefabricated building of parts permits engineering as well as other function to carry on extra rapidly and with much less means on web site since the web site is starting to glimpse a lot more of a location for assembly, making use of things which are pre-fabricated. Prefabricated parts are built using a number of software package that specially allows the generation of MEP (M&E) prefabrication modules and plant skids along with structural and architecturally made properties and making factors. We glance at a few of the different types of prefabrication in building as well as program that allows it, together with BIM (Making Data Modelling) engineering.

Prefabricated development services or Design for Manufacture and Assembly (MEP Global Engineering - Top MEP Design and BIM Company) or modular construction companies as They are really acknowledged, are commonly perceived to apply to accomplish models for traditional use. But modular design includes over that. It includes a wide selection of sub-assemblies and prefabricated aspects, for example fire stairs, elevators, plumbing, heating and cooling and ADA-compliant spaces, that may be produced off web-site and transported to the worksite. Additional complex aspects of the setting up, for instance a facade with panels, is usually prefabricated. Even subcomponents which can be repeated through a job, for instance affected person rooms in health care amenities, bathrooms, lecture rooms and science labs in instructional institutions, lend by themselves to the process of prefabrication. MEP Design - Drafting The numerous array of prefabricated elements can be broadly categorized into 3 sorts: structural, architectural and engineering-related. Each of those MEP Global Engineering - Top MEP Design and BIM Company elements are explored in more depth in this article.

Structural Prefabrication:

The options for MEP Global Engineering - Top MEP Design and BIM Company are Just about countless inside the structural design and style Room. Tall tower blocks or huge halls, wherever even load-bearing partitions, at the same time, as retaining partitions of L form, are elements of a construction which can be prefabricated. Load-bearing partitions are commonly exterior walls of a creating and may even be walls concerning apartments, which bolster the framework's rigidity and these can now be produced off web-site and delivered to site. Forged in molds for prefabrication are waffle models, put in grid patterns, which might be used for flooring/roofing. Other aspects routinely prefabricated, possibly as complete models or various ingredient parts for assembly on web site, involve:

For buildings that use metal frames, it is possible to fabricate various tales without having pillars, beams and concrete. These steel frames are created and manufactured from Laptop or computer designs specifically linked to CNC (Laptop numerical control) equipment, guaranteeing superior levels of accuracy and velocity of erection.

Suited to residential structures, prefabricated box element engineering includes a process exactly where a framework is assembled with ready-to-assemble box units off site. These kinds of box aspects commonly contain a load-bearing frame, partitions, flooring in addition to a roof, with Home windows, HVAC and electrical gear and fittings.

Architectural Prefabrication:

Obviously, most of the structural aspects crafted will also be considered to be architectural features as well as the detail that is certainly established for a similar involves the architectural layout and making code needs for off-web page manufacture. Prefabrication factors frequently Employed Plumbing Design-Drafting in architecture

Incorporate:

Engineering Prefabrication:

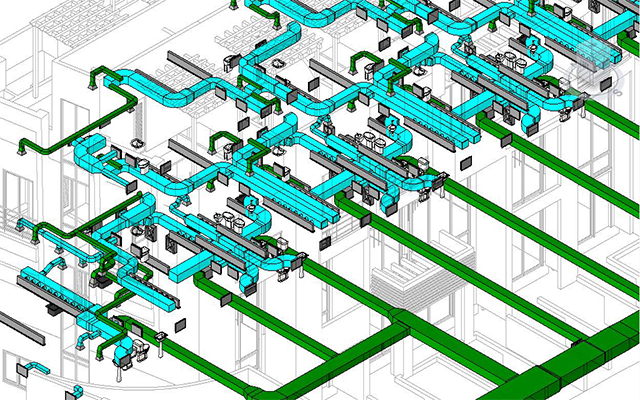

Prefabricated, reinforced and pre-pressured factors of advanced technological and sophisticated structure are Utilized in the engineering factors of assignments far too. Prefabricated elements utilised in engineering involve a number of unique factors, including the assemblies of: A modular procedure skid, or plant skid, is a method inside of a body that is well transported. Particular person skids comprise method devices, and various process skids might be assembled to generate complete moveable plants, in some cases generally known as 'a process in a very box'. Multi-skid method methods may perhaps consist of coordinated raw supplies skids, utilities skids and processing models. Multiple skids allow parallel design.

A plant area, mechanical space or a boiler home, is usually a space or region inside a structure that is dedicated to mechanical tools and linked electrical tools, all of that may be prefabricated. The plant space usually has the next: Modular ceiling and riser methods encompass constructing parts to retail outlet, method and approach. These programs ensure it is a lot quicker and simpler to assemble the setting up companies Remedy on web site. Prefabricated factors are useful as plant skids, in plant rooms and as ceiling and riser modules simply because they have currently regarded https://en.wikipedia.org/wiki/?search=MEP BIM Coordination & Clash Detection,Clash Detection & Coordination Services all hanging and attachments to your module and therefore hangars and fitting individual providers on internet site aren't essential. Commonly, these modules are created in the course of the 3D BIM coordination stage, in which before setting up will allow a more effective format.

Application:

Prefabrication for architecture, composition and MEP (M&E) expert services is useful for an economical and successful prefabrication course of action. A lot of the far more well-liked computer software

Answers utilized include:

AutoCAD, Revit, Inventor, Fabrication The popular software program for prefabrication in development are Revit, AutoCAD and Inventor. They supply: For the duration of design, SDS/two, IDAT Precast and Autodesk Fabrication are applicable software program selections that help the generation of precise structural and MEP 3D styles for prefabrication. Additionally, Autodesk's Revit computer software functions efficiently Together with the producing functions of Autodesk Inventor to deliver prefabrication modules.

The prefabrication model by Inventor communicates any alterations Together with the architectural design and style and the Computer Numerical Management (CNC) factors. For every form of prefabrication module, one Revit team will determine the discipline element. All discipline styles will need to have aspects in order that modules are geometrically divided. This file can be utilized as a whole module for prefabrication. For each type of prefabrication module within a venture, there exists a single exclusive module model. Any module team/assembly might be updated, altered, replaced or deleted, though Each individual https://www.washingtonpost.com/newssearch/?query=MEP BIM Coordination & Clash Detection,Clash Detection & Coordination Services deviation is audited, recognized or denied.

At this stage, a BIM workflow to the drawing and Examination of prefabricated modules may be produced in Revit. It may then observe alterations. That has a file in the modules' prefabrication parameters, info is usually counted, analysed and translated. With all the parameter values, filters and module-precise views could be established, facilitating coordination in between the different undertaking groups.

In AutoCAD, a schematic drawing of a prefabricated aspect variety and dimension values of the concerned part are displayed. It may then crank out 3D drawings of described Clash-free models in Navisworks elements and aspect parameters are specified.

Autodesk's Fabrication CADmep™, Fabrication ESTmep™ and Fabrication CAMduct™ application aid element and fabricate better structures. BIM 360 Team, Revit, and Fabrication equipment can talk, view, mark up and assessment undertaking design documents from wherever, and keep connected to the extended design and style group.

SEMA:

With refined information and macro systems, SEMA software package can be adapted to the specific demands of a business. SEMA supports prefabricated design with very simple operations to put features in roofs, ceilings or partitions in a quick and productive way.

SEMA attributes extensive editing features and regular 3D graphic updates to double-Verify the construction. Layouts and drawings with purchaser inputs are swiftly created. Versatile macros are supplied, especially for stairs.

SEMA also supplies 3D visualisation from a number of angles. The 'environment' of objects, which include walls, Home windows, ceilings or home furniture, is often seen with photorealistic displays, and a variety of practical 3D objects for visualisation can be found. Also, 3D objects is usually imported. Gentle and shadow measurements contribute on the Visible actuality of your objects.

The scale of an item in its unfinished state can be used to work out figures, in just a few minutes, for quotations in design. In-depth assembly points, for instance reference points for fixing bracket methods, might be calculated to your millimetre. SEMA delivers substantial libraries of fasteners, brackets, close types, tenons, scarf joints, lamellar connectors, dowels and metal connections with bolts.

Solidworks:

Simple to operate, easily adaptable for rising parts that may be tough to generate, which include curved stairs, Solidworks, part of Dassault Systemes, is effective for developing large-close factors. It will increase productiveness, with a variety of information and specialized communication input and offers simulation technological innovation to help you verify patterns. Solidworks automates the purchasing, configuring, developing and developing of prefabricated elements. It features Good Modelling, Movement, Simulation, Toolbox, TolAnalyst, Circute