Homes tell their stories through small shifts. A hairline zigzag in the basement wall, a sticky door in late summer, a stair-step crack wandering across brick. Some of these are harmless, the kind of movement you expect as seasons swing and soil breathes. Others point to structural trouble. The art is knowing which is which, then hiring the right hands to fix the problem with the right method at the right price. That takes judgment and a working understanding of how foundations behave, how contractors bid, and how repair materials perform over time.

I spend most of my days under porches, inside crawlspaces, or staring at concrete the way a doctor studies an X-ray. The work has a rhythm. Diagnose the cause, not just the symptom. Choose the least invasive solution that will stay fixed. Tell the truth about cost and disruption. The sections that follow collect that field experience into practical guidance, with a focus on homeowners comparing foundation crack repair companies, assessing bids in and around St Charles, navigating trees near foundations, and deciding between epoxy and polyurethane injections. We will also talk about the real costs behind “epoxy injection foundation crack repair cost,” maintenance strategies that keep water away from your walls, and what to expect after injection in terms of curing times and re-entry.

Reading BBB Ratings without getting fooled by the numbers

The Better Business Bureau rating has become a quick proxy for trust. It is useful, but not complete. A contractor can have an A+ and still be a poor fit for your project. BBB scores are built on complaint history, time in business, transparency, and how a company responds to issues. That means a new firm with excellent work but only two years of history might be graded lower than an average shop with a decade of paperwork. On the other hand, a high rating with a string of unresolved complaints is an obvious red flag. Read the complaint patterns, not just the stars. Look for concentration around warranty call-backs, oversold solutions, or aggressive sales practices.

When you search foundations repair near me, the first page will show a mix of national brands and local outfits. Use BBB to filter the noise. Aim for contractors with established records in your climate and soil, a responsive complaint resolution track, and detailed profiles that list services beyond “foundation crack repair companies.” A healthy firm will show permits pulled in your municipality, photos of residential foundation repair, and references you can actually call.

I keep a short list of questions that cut through marketing. Ask how many epoxy injection foundation crack repair projects they completed last year. Ask if they staff their own injection techs or sub them out. Ask for three recent jobs within ten miles of your home. The answers tell you whether you are talking to a sales office or to a team that will be responsible for your basement wall when the next heavy rain hits.

St Charles homeowners: how to compare foundation repair bids that look nothing alike

If you live in St Charles or the Fox River Valley, you know the soil runs from silty loam near the floodplain to glacial tills with pockets of expansive clay. The variety matters. Foundation repair St Charles contractors price the same crack differently depending on depth, access, and water pressure. I https://edgarjjry603.theglensecret.com/foundation-crack-repair-cost-diy-vs-professional have seen three bids on the same house range from a few hundred dollars for a polyurethane injection to five figures for exterior excavation and wall waterproofing. Both can be right, depending on context.

Get at least two written bids. More is fine so long as you compare apples to apples. Some contractors will suggest interior injection for non-structural cracks that leak but do not move. Others will push carbon fiber straps for lateral wall movement measured in inches. The key is understanding what is included. Does the bid cover re-routing a downspout extension as part of drainage work? Does the price include grinding wall coatings to clean the crack before injection, or are they injecting over old paint that will prevent bond? In St Charles, basement wall humidity swings with the river levels and seasonal groundwater, so the prep step matters. Moist or damp cracks make polyurethane more forgiving than epoxy. That nuance should show up in the bid.

I encourage homeowners to do a simple walk with each estimator. Ask them to show you where they think water is entering and why. If an estimator is willing to spend five minutes outside with you, looking at grading, gutters, and driveway slope, that is a good sign. If they go straight to the wall and sell a product without talking about surface water control, keep looking.

Normal cracks versus structural cracks, the line that separates nuisance from risk

Not every crack signals foundation structural repair. Concrete shrinks as it cures. A narrow, vertical crack starting at a window corner and running down a foot or two often falls into the normal category, especially if it has not widened over the years. Horizontal cracks in concrete block walls, bowing greater than about one inch, or stair-step cracks in brick that open and close with the seasons lean toward structural. So do diagonal cracks from the corners of doors or egress windows that drag the header down.

Document changes. Use a pencil and mark the ends of a crack with the date. If it grows, you will see it in six months. I have also used inexpensive crack monitors or even calipers for repeat measurements. Movement is the tell. For structural movement, foundation stabilization methods range from helical piles to wall anchors and carbon fiber, each matched to the failure mode. For non-structural cracks that leak, injection or exterior patching is the typical fix.

If you look up foundation experts near me, you will find firms that specialize in one remedy. That skews recommendations. A pier company might prescribe piers even when surface drainage would solve the problem. A waterproofing company might pitch a full interior drain tile for a single leaking crack. Choose firms that offer multiple tools, or at least explain why one method fits your specific condition.

Trees near the house: helical piles and the reality of roots

Trees complicate foundations in two main ways. In expansive clays, large trees can pull moisture from soils during dry spells, shrinking the soil and causing settlement on the tree side. In looser or organic soils, roots can displace light structures and create voids under walks and slabs. When a house needs support near a tree, helical piles for house foundation are a solid option because they are installed with torque, not excavation, and they can thread through root zones with minimal cutting.

I have installed helical piles within six feet of mature maples without significant root damage by adjusting the helix depth and layout. The rule is to avoid severing large structural roots, usually anything over 2 inches in diameter within the top 12 to 18 inches of soil near the trunk. An experienced installer will probe, shift locations by a foot or two, or angle piles to preserve major roots. The torque readings during installation confirm bearing capacity at depth, often well below root influence. If you need to underpin or support a porch column near a tree, helical piles keep the work surgical and avoid the big trench that would harm the root system.

There is a flip side. If the tree sits in a highly expansive clay zone, removing it can cause heave as the soil rehydrates over a few seasons. That means today’s settlement might become tomorrow’s uplift. Before you remove a tree to solve a foundation problem, talk through the soil mechanics with someone who has worked your block. Sometimes the better path is to stabilize the foundation with piles, adjust drainage, and leave the tree alone.

Epoxy injection versus polyurethane injection: choosing what belongs in the crack

Both materials have a place. I carry both in the truck because the right choice depends on the crack’s role. Epoxy is a structural adhesive. When the crack is clean and dry enough, and the wall has not moved more than a small amount, epoxy can knit the concrete back together. The cured bond can reach strengths comparable to the original concrete. That makes epoxy good for tight, non-moving cracks where restoring continuity matters, for example a vertical crack in a poured wall that will otherwise propagate under load.

Polyurethane is a reactive foam. It expands when it meets moisture, chases water paths, and forms a flexible seal that tolerates a bit of movement. That makes it ideal for wet, actively leaking cracks. In a basement with seeping joints after a storm, polyurethane will find the water and seal it. It will not restore structural capacity, but most leaking cracks are non-structural, so that is fine.

There are edge cases. Cold weather slows epoxy cure, and in a damp basement where dew settles on the wall, epoxy can fail to bond unless you dry and preheat the area. Some polyurethane formulations are hydrophobic, some hydrophilic. Hydrophilic foams swell with water then shrink when dry, which can re-open paths during droughts. Hydrophobic foams resist that swing. A seasoned injector will choose the resin based on crack width, moisture, and the wall’s future movement.

For homeowners asking about epoxy injection foundation crack repair cost, assume a wide range. For a single, accessible crack about 8 to 10 feet tall, costs often land between 400 and 1,200 dollars, depending on region, prep time, and whether follow-up visits are included. In foundation repair Chicago markets, labor rates and access can push pricing higher. If the crack is buried behind finished walls, add demolition and patching. Multiple cracks sometimes price more efficiently when done in one mobilization. Polyurethane is often priced similarly, with a slight tilt toward polyurethane being less expensive on very wet cracks because it tolerates less prep.

Managing the long game: maintenance that protects your injection investment

An injection is only as good as the water management around your house. I have returned to re-inject the same crack in homes where gutters dump at the foundation, window wells fill like aquariums, and soil slopes toward the basement wall. Fixing the source reduces pressure and makes any injection last.

Think in layers. Roof water needs a place to go that is not your footing. Extend downspouts 6 to 10 feet away, more if your lot allows. Keep gutters clean, especially under tree canopies. Check the grade. Soil should drop at least 1 inch per foot for 5 to 10 feet from the foundation. Add compacted clay or loam, not mulch, to build that slope. Seal driveway and walkway joints where they meet the foundation, since those gaps funnel water directly to the wall.

Inside, monitor humidity. High basement humidity can condensate on cold walls and mimic leaks. A simple hygrometer tells the truth. In older homes, installing a small dehumidifier during sticky months keeps the environment steady, which helps coatings and adhesives last. If you have an interior sump system, test it before peak rain seasons. A failed pump turns minor cracks into gushing inlets.

Maintenance also includes the patience not to overreact. Some hairline cracks do not need injection. If a crack is not leaking, has stayed the same width for two or more years, and shows no signs of efflorescence, leave it alone. Document, watch, and spend your money on drainage. That restraint saves budget for when a real problem appears.

How reputable foundation crack repair companies structure warranties

Warranties vary wildly. A lifetime warranty that excludes hydrostatic pressure or excludes “movement” often covers very little. Good firms write clear terms. For polyurethane injection, many offer warranties against water leakage at the injection site for periods of 3 to 10 years. For epoxy, structural warranties are harder to write unless the crack is part of a broader stabilization plan. Read for transferability if you plan to sell, and for conditions that void coverage, such as failure to maintain drainage.

A foundation crack repair company that ties its warranty to measurable conditions is doing you a favor. I have language that requires downspout extensions to remain in place and exterior grade to be maintained. It is not because we like rules. It is because we know pressure drives leaks. The warranty is a partnership.

What to expect on injection day: prep, curing, and when you can go back downstairs

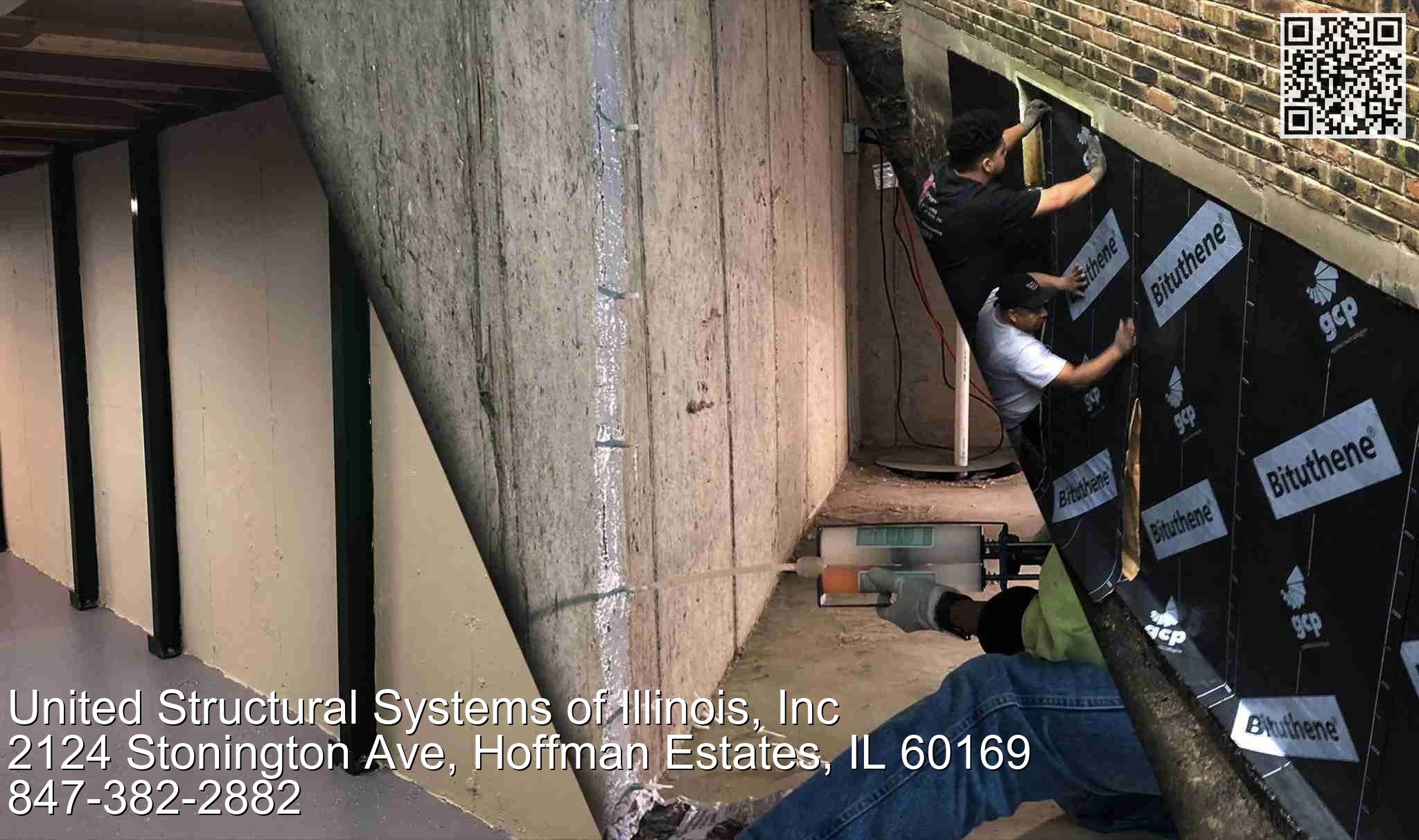

Foundation injection repair is tidy compared to excavation, but it is still a construction activity with adhesives and resins that need time to cure. The technician will grind or scrape a narrow path along the crack to remove paint or efflorescence. Ports get glued along the crack with a surface paste. The crack is then sealed on the surface to contain the resin while it travels inside.

For polyurethane, active leaks are not a problem. In fact, moisture helps the resin activate. After injection, the foam will expand within minutes and gel in place. Most polyurethane systems allow normal re-entry to the basement within an hour or two. Odor is minimal with high-quality products, especially the low-VOC formulations. If the area is poorly ventilated, crack a window or run a small fan.

Epoxy lives on a different timetable. It prefers a dry or at least not dripping crack. After injection, epoxy can take 12 to 48 hours to cure depending on temperature and product. At 60 to 70 degrees Fahrenheit, many epoxies are tack-free in a few hours, then build strength over a day or two. Warmer temperatures accelerate the process. During cure, avoid impacts to the wall near the crack. Leave the ports on until the technician returns to remove them or grinds them off. Re-entry into the space is usually safe the same day, but avoid touching the paste or ports.

If the basement is finished, protection matters. Ask the crew how they plan to cover floors and isolate dust. A careful team brings drop cloths, plastic, and a HEPA vacuum. Good communication about curing times and re-entry prevents the classic scenario where someone peels off a still-green surface seal or bumps a port while moving storage back too early.

Comparing costs honestly: the quiet drivers behind the invoice

That “foundation crack repair cost” on a website is often a teaser. The real price reflects five variables: access, prep, moisture, length, and finish. Access includes working space, wall coverings, and the time to move obstacles. Prep means grinding paint, routing the crack slightly for injection contact, and cleaning. Moisture dictates product choice and sometimes extra steps, like drying with heat for epoxy. Length is literal. A 4-foot crack costs less than a 12-foot crack, but not always in a straight line because setup has a fixed component. Finish involves port removal, surface patching, and any cosmetic repainting.

Regional labor rates also matter. Foundation repair Chicago crews carry higher overhead than rural shops, from parking to insurance. That shows up in the cost range. On the flip side, urban crews often have more experience with a wider variety of conditions, which can translate to faster, cleaner work.

Bundling helps. If you have three cracks to fix, ask for a combined price while the crew is mobilized. If the contractor is already on-site installing helical piles or an interior drain, injection of incidental cracks may be priced more favorably. Transparent companies will tell you when a crack can wait, rather than pushing to “do it all today.”

When injection is not enough and stabilization enters the picture

Some cracks tell you to look deeper. A horizontal crack with inward bow on a block wall is not a candidate for injection as a standalone fix. That wall needs lateral support. Carbon fiber straps help when bow is modest, usually under an inch. Wall anchors or steel beams address greater movement. If settlement has opened diagonal cracks that widen toward the top, the footing may have dropped. That is where underpinning comes in. Helical piles or push piers transfer load to deeper soils, then the cracks can be stitched or injected after lift or stabilization.

Homeowners sometimes ask for the lowest-cost path, which is understandable. I have had to say no to a simple injection when the structure demands more. A temporary seal that traps water in a moving crack can cause further damage. A responsible contractor will explain the sequence: stabilize first, then seal.

Two simple checklists for picking the right partner and for preparing your home

Checklist for selecting a contractor with BBB sanity checks:

- Verify BBB rating, then read complaint patterns and resolutions for the past 36 months. Ask for three recent local references with similar repairs, then call them. Confirm the company performs both epoxy and polyurethane injections, or can explain the limits of a single method. Request proof of insurance, city licensing where applicable, and a sample warranty. Compare bids line by line for prep, product, length, access, and finish, not just total price.

Checklist to prepare your home for injection day:

- Clear 3 to 5 feet of space along the wall, including removing shelves or storage. Mark cracks you want addressed with painter’s tape so the tech sees them all. Confirm access to a standard electrical outlet and a hose bib if water is needed. Plan ventilation if the basement is tight, a box fan in a window works well. Keep pets and kids upstairs until the technician gives the all-clear.

A note on safety, VOCs, and homeowner comfort

Modern resins have come a long way. Reputable suppliers offer low-odor, low-VOC formulations that are safe for occupied homes when used correctly. Still, sensitive individuals might notice a mild chemical smell, especially with surface pastes that contain solvents. If you are sensitive, tell your contractor ahead of time. They can choose products that minimize odor and schedule work earlier in the day to allow longer cure before evening.

Personal protective equipment is a sign of professionalism. Technicians should wear gloves, eye protection, and respiratory protection as needed. If your contractor shows up without basic PPE, that speaks to their culture and care. The same goes for cleanup. A clean job at the end is the mark of a crew that respects your space.

How to handle repeat leaks or call-backs without drama

Even good injections can have a pinhole miss or a secondary path that shows itself after the next big storm. Water follows the path of least resistance. If you see moisture near, but not exactly on, the injected crack, take photos and note the timing and rainfall. Call your contractor calmly with that information. Most warranties anticipate a return visit for touch-ups. It is part of the process, not a failure of character. A solid company will schedule a quick return, pressure-test the area, and re-inject as needed.

If the leak is elsewhere, especially at a joint or pipe penetration you had not noticed before, ask whether it can be added to the scope while the technician is already on-site. Often that add-on is more economical than a new visit later.

Pulling it together: spend money where it matters, but spend it once

A foundation is not fragile, but it responds to water and soil like any structure would. If you learn to read the signs, you can sort foundation cracks normal from those that call for action. When action is needed, choose the method that matches the cause. For wet, non-structural cracks, polyurethane injection is a reliable, forgiving seal. For dry, tight cracks where structural continuity matters, epoxy is the right tool. Keep an eye on the broader system. Grading, gutters, and surface seals do as much for your basement as any resin.

As you navigate foundation crack repair companies and parse BBB ratings, ask for specifics, not slogans. In places like St Charles, context is king. Soils change from block to block, trees pull and release moisture, seasons test your system. If stabilization is required, helical piles give you a precise, minimally disruptive option, especially near tree roots. And if what you need is a single clean injection, do it well, take care of the water outside, and you will likely not see that crack again.

When I finish a job, I like to take one last slow walk with the homeowner. We look at the repaired wall, then the downspouts, the slope, the sidewalk joint caulks. That loop is the real fix. It is how you turn a one-time repair into a durable home, the kind that stays easy to live in and easier to sell.

Working Hours Mon-Fri 8:30am-5:00pm Sat-Sun By Appointment United Structural Systems of Illinois, Inc 2124 Stonington Ave, Hoffman Estates, IL 60169 847-382-2882

Services Structural Foundation Repair Foundation Crack Repair Services Residential Basement & Crawlspace Waterproofing Helical Pile Installation Commercial Helical Pier Installation Helical Tieback Anchor Installation Resistance Piles and Micro Piles