Spring roll wrappers are a foundational component in many Asian and fusion cuisines, valued for their thinness, elasticity, and consistent texture. As global demand for spring rolls continues to rise, manufacturers face increasing pressure to scale production while maintaining uniform quality. The automatic spring roll wrapper machine has emerged as a critical solution, enabling efficient, hygienic, and highly consistent wrapper manufacturing.

What Is an Automatic Spring Roll Wrapper Machine?

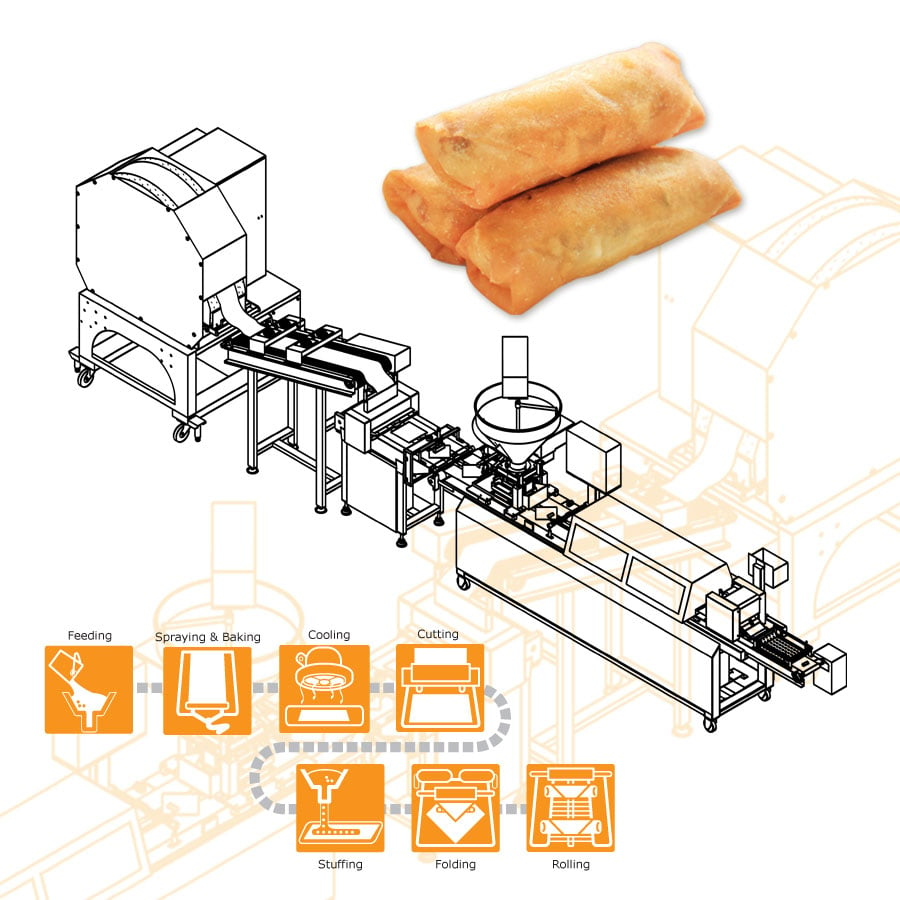

An automatic spring roll wrapper machine is an industrial food-processing system designed to continuously produce thin sheets of spring roll pastry. By automating batter spreading, baking, peeling, cutting, and stacking, the machine replaces labor-intensive manual methods with a streamlined, repeatable process suitable for medium to large-scale production.

How the Machine Works

The production process is engineered for precision and consistency:

-

Batter Feeding – A liquid batter, typically made from wheat flour, water, oil, and salt, is pumped into the system at a controlled rate.

-

Sheet Forming and Baking – The batter is evenly spread onto a heated rotating drum or conveyor, where it is baked into a thin, uniform sheet.

-

Peeling and Cooling – Once cooked, the wrapper is gently peeled from the heating surface and cooled to preserve flexibility.

-

Cutting and Stacking – The sheet is cut into standardized sizes and stacked automatically for packaging or further processing.

This closed-loop operation minimizes human contact, improving food safety and production efficiency.

Key Advantages

1. Consistent Quality

Automated control of thickness, moisture, and baking temperature ensures each wrapper meets the same quality specifications, batch after batch.

2. High Production Capacity

Depending on the model, machines can produce thousands of wrappers per hour, making them ideal for commercial food factories and export-oriented businesses.

3. Labor and Cost Efficiency

Automation significantly reduces the need for skilled manual labor, lowering long-term operating costs and dependence on workforce availability.

4. Hygiene and Food Safety

Stainless steel construction and enclosed processing zones help manufacturers comply with international food safety standards such as HACCP and GMP.

5. Customization Flexibility

Many machines allow adjustments to wrapper size, thickness, and moisture content, supporting different product formats such as fresh, frozen, or ready-to-fry spring rolls.

Applications Across the Food Industry

Automatic spring roll wrapper machines are widely used by:

-

Frozen food manufacturers

-

Central kitchens and catering companies

-

Asian food processing plants

-

Export-oriented pastry and wrapper producers

Beyond spring rolls, similar machines can often be adapted for samosa sheets, egg roll wrappers, or other thin pastry products.

Considerations When Choosing a Machine

When investing in an automatic spring roll wrapper machine, manufacturers should evaluate:

-

Production capacity requirements

-

Wrapper size and thickness range

-

Energy efficiency and heating method

-

Ease of cleaning and maintenance

-

After-sales service and spare parts availability

Selecting the right configuration ensures the machine aligns with both current demand and future growth plans.

Conclusion

The automatic spring roll wrapper machine represents a significant advancement in food processing technology. By combining speed, precision, and hygiene, it allows manufacturers to scale production without compromising quality. For businesses aiming to remain competitive in the growing global convenience food market, adopting automated wrapper production is no longer a luxury—it is a strategic necessity.