Most business structures perform their task without excitement, straight up until they perform not. The instant a piece pops all over a cavalcade line, or even a tilt-wall panel slips out of aircraft after a heavy storm, the discussion adjustments coming from regimen upkeep to tons roads, dirt habits, and also exactly how to relocate forces securely to something that are going helical pile foundations to certainly not press further. Protection piles, helical piles, and also micropiles sit at the center of that chat. Each unit has a character, a technique it engages the ground, as well as a set of details that make a decision whether a repair for many years or even needs a second attempt.

I have actually designed and also put up all 3 units under healthcare facilities that could certainly not finalize, under data facilities where vibration tolerance was evaluated in thousandths of an inch, and also in precarious alleys responsible for famous block exteriors. The best selection usually comes from weding geotechnical fact along with constructability, then showing capacity in the business. The segments listed below rest the subject matter down the technique our company manage it on active ventures, not in theory.

Where resistance piles fit in the business toolkit

Commercial resistance pile setup solves a basic complication: transactions building bunches by means of poor, compressible soils into something stiffer below. Unlike a driven stack with a hammer, a protection or press boat dock innovations through gas rams responding versus the property\'s weight, mounting steel segments up until idea resistance reaches an indicated power. That creates them superb for structural foundation repair where resolution has actually developed and also you need to have both new help and also the option to lift.

Helical piles solve an associated complication differently. Their helix plates partitioned the soil at a continual pitch, changing torque into axial capacity. They work when you can easily certainly not react versus existing weight, when you need to have strain ability, or even when soils are sensitive to vibration. Micropiles make use of high-strength steel as well as cement to bring bunch primarily through connection along their length. They are the cosmetic surgeon's device for strict internet sites, overhanging open space limits, or even heterogeneous dirts where a punched, grouted aspect supplies predictability.

These three bodies, in addition to helical tieback anchors for side restraint, deal with most commercial foundation stabilization instances. A falling short slab-on-grade at a retail box may choose resistance heaps below quality beams for upright load as well as helical tiebacks to bandage an accepting wall. A brand-new mezzanine in a plant may call for commercial helical pile installation due to the fact that you can easily thread tools in between real-time process lines without a crane. Micropiles usually win listed below existing lift primaries, smokestacks, and health centers where resonance as well as noise should be minimal.

Soil manages the conversation

Ignore the soil at your hazard. I have actually found projects try to utilize helical anchors in retractable loess that went smooth after storm, or even protection piles in an illumination, steel-framed structure that just could certainly not deliver adequate response. An excellent subsurface inspection purchases itself several opportunities over.

What matters most for these devices:

Stratigraphy and also irregularity. Layered clay-baseds over sand, or even full of building and construction fragments, can easily alter range over a few feet flat. On a distribution facility in southern Indiana, two adjacent columns acted in different ways given that a buried demolition trench operated between all of them. Our experts adjusted the stack lengths through much more than 10 feet over a 40-foot bay once the verification lots informed the story.

Shear stamina and abrasion angle. Helical piles bank on undrained shear stamina in clays and also on abrasion in sands. Torque-to-capacity connections just hold if you know the dirt profile.

Groundwater and also artesian conditions. Micropiles rely upon cement connection as well as canvassing security. In moving sands, you may need short-lived housing and a more thick grout mix to stay clear of dilution.

Obstructions. Cobble lenses, ashes, and caliche can easily stop helical piles cool or draw away rotary tool cords for micropiles. Resistance stacks along with sharp recommendations as well as high jacking forces often drill by means of, but even after that you risk heap imbalance without careful guidance.

Design fundamentals that keep you away from trouble

Capacity, stiffness, and also redundancy separate strong deep foundation repair from a Band-Aid. I tend to move toward the style in 3 layers: geotechnical ability, structural adequacy of the heap system, and also payload transfer via brackets and also existing concrete.

Geotechnical capacity. For resistance piles, a lot of capacity comes from end bearing at the tip when you hoist right into a dense level or even stone. The industry jacking tension delivers a direct pathway to confirming greatest ability, with an aspect of security put on determine permitted payload. For helical piles, ability is a total of helix bearing surface areas or even derived from twist relationship (usual worths range 7 to 12 in-lb every ft-lb for square-shaft and also round-shaft units, depending on producer as well as soil). Micropiles rely on grout-to-ground connect along a described span, commonly 60 to 200 psi for clay-baseds and 200 to 400 psi for sands as well as rocks, along with greater market values in rock sockets.

Structural capacity. The steel shafts and brackets need to stand up to the demanded bunches along with necessary safety and security aspects and also corrosion allocations. A common trap is actually over-reliance on torque market values to proclaim a helical pile "excellent" while overlooking that the shaft itself possesses a bending limit in soft clays under squeezing. Use stiffer round-shaft helicals, sleeves, or even cement columns where fastening is a risk. For micropiles, inspect the steel primary in strain and squeezing, the grout body system in compression, and also composite activity with casing if it remains.

Load transfer to the framework. Brackets issue. A retrofit bracket for commercial foundation repair needs to have adequate bearing and also embedment into the existing ground or level beam to stay away from hitting or even splitting. Where bases are actually slim or even riddled along with rebar conflicts, our team either include local thickening, stitch new level shafts, or spread loads over various heaps at lesser personal capacity. For slabs, I prefer to prevent slab-only brackets and also as an alternative reduced and link into a shaft or brand new boat dock hat. Pieces are unsatisfactory bunch transmission elements unless designed as such.

Choosing in between resistance, helical, and micropiles

Cost every pile is actually the wrong statistics. Price per kips of validated capability at company weights, delivered in the space and also timetable you really possess, is actually a much better lens.

Resistance piles shine when the structure is actually heavy good enough to deliver reaction as well as when edge bearing may be gotten to in a realistic deepness. They are actually excellent for founding columns, tilt-wall doors, and hefty stonework. They also permit measured airlift in the course of setup. The weakness: a lightweight building may certainly not let you propel sufficient mounting force, and soft layers over heavy layers can induce lengthy stack durations with improving cost.

Helical heaps bring compression and stress, put up quickly, and also deliver clean QA using torque. They prevent vibration, creating them excellent for health centers, laboratories, and information facilities. They despise debris fills and also patches, which can easily twist coil platters or stall infiltration. Square-shaft helicals give far better torsional stamina in hard clays, while round-shaft piles provide hardness in squeezing and lower buckling risk in delicate soils. Helical tieback anchor devices are the side friend for preserving walls, basement walls, as well as braced excavations. Commercial helical tieback anchor installation typically features evidence filling to 120 to 150 per-cent of style strain and also lock-off at company load.

Micropiles go where absolutely nothing else can. Small rigs travel through 8-foot doors. Studied exploration manages collapsible grounds. Cement bond creates ability less sensitive to separate impediments. They are actually versatile for deep foundation repair under existing frameworks, however product as well as mobilization expenses every heap can be higher. In rock, tight pressure-grouted outlets supply enormous ability in cramping footprints.

Installation realities that make a decision success

On a retrofit at a medical office building, our team possessed 5 weekend breaks to support and raise a settled corner where differential had connected with virtually 1.5 ins. The plan incorporated protection piles for airlift as well as helical tiebacks to respond to small sidewise ground tension on a cellar wall structure. What created it work was actually not creative math, it was actually strategies and sequencing.

Access. Think of just how equipment gets inside and also out, where spoils go, and also how to manage slurry or even cement in busy properties. Commercial micro pile installation usually needs a clean grout plant setup, spill control, and also washout management. Helical pile rigs are nimble, but you still need to have a course for 10 to 20 foot lead segments or even interlaced sections. Protection stacks demand a clear face at the footing and area to phase gas pumps as well as gauges.

Measurement and tolerances. For resistance stacks, make use of adjusted evaluates as well as document jacking powers as well as airlift increments. Footing lift ought to be sluggish and consistent, commonly a handful of millimeters every elapsed across multiple heaps to avoid cracking. For helical piles, watch both twist as well as pitch every revolution to confirm accurate advancement, not ground disturbance. For micropiles, screen cements take and also stress; an unexpected reduce may show a space or a reduction zone that calls for packers or even presented grouting.

Obstructions and changes. Presume a minimum of 10 to twenty percent of sites will differ consider existing structures. Maintain alternate stack key ins the script. On one stockroom task where helical piles fulfilled bouldery antarctic till, our experts moved a 3rd of the locations to micropiles with quick stone outlets as well as maintained the timetable through mobilizing a small drill midweek.

Noise and vibration. Helical piles as well as micropiles get along to sensitive lessees, however drilled work still produces some noise. Resistance pile installment develops recognizable gas pump sound and can shake local elements during airlift. Correspond with dwellers, schedule raucous periods properly, and also mount resonance displays near delicate finishes or tools if thresholds are actually tight.

Capacity proof and also quality control on site

You carry out certainly not acquire what you style; you acquire what you assess. In commercial helical pile installation, the torque log is your very first top quality examination, but I still such as to proof load a representative example, specifically in split profiles where twist correlation may float. Typical technique: bunch to 1.5 to 2.0 opportunities layout, support and notice creep. For pressure helical anchors as well as tieback anchors, proof and also, for some, functionality examinations are standard, along with lock-off at service tons after reasonable creep.

Resistance stacks give urgent feedback through jacking stress and also variation. Our company track hoisting force versus step-by-step action to make sure our experts are not just squeezing delicate strata without reaching end bearing. After lock-off, a lift-readiness examination makes certain stacks discuss tons. If one place shows major action at moderate force, suppose a regional weak spot and also incorporate a pile or even increase embedment at adjacent points.

Micropiles are assessed via cements take, connection size, and also, on chosen heaps, squeezing or even tension screening. Where our experts anticipate high capacity coming from connect in heavy sand, our team usually include a proof stack with an Osterberg tissue or even a typical static tons examination. It is not affordable, but on projects along with numerous micropiles, one fell short concept expectation costs more than a well-instrumented test.

Structural details that wait together

Most breakdowns I have actually looked into in structure repair work carried out not begin in the ground, they started at the interface. Brackets that split a footing, anchor bolts that gave in the course of lift, or welds that bashed coming from eccentricity may threaten typically sound piles.

For resistance pile braces, spread out the response. I prefer braces that engage under the ground along with a seat layer and also mechanical hookup instead of bearing on a slender slant. Where existing grounds are superficial, our team core or even chip pockets, spot improving dowels with effective embedment, and directed a cement buttocks to supply a clean bearing area and to circulate lots into the ground. On heavily jam-packed columns, our company sew a brand new pile hat around the ground, tie in to the existing along with epoxy pegs, and land a number of heaps into that hat to share load.

For helical piles sustaining brand new steel columns, line up the heap head with the column tons pathway, prevent large eccentricities, and style for both squeezing as well as uplift if the use can easily modify. In seaside applications, corrosion allotments as well as hot-dip priming extend service life, as well as in aggressive soils our team incorporate sacrificial fullness or even cathodic security per the geotechnical report.

For micropiles, tons transmission takes place at a heap limit or even quality beam. The steel pub or even casing ventures in to the hat, built by connection and also technical hardware. Our company check club growth, ensure enough shear rubbing all over any construction joint, and feature prison reinforcing to manage strong strut-and-tie paths.

Lifting resolved designs without developing new problems

Many proprietors seek airlift to recover doors, windows, and also piece slopes. Raise is possible with resistance piles and also, sometimes, with helical piles utilizing hoisting scalps. The adversary resides in the rate as well as the pattern.

We begin by pinpointing what should relocate with each other. On a two-story office airfoil, our company lifted exterior grade shafts as well as interior pillar footings in a worked with pattern, no greater than 1/8 in per airlift pass, smoothing with 6 to 12 piles in a loop. A laser level tracked family member motion. Interior finishes broken at a handful of joints, but primary grief was avoided. When aim at altitude is actually gotten to or even the construct ceases reacting without extreme pressure, our experts latch off. Count on partial recuperation, not perfectness, when curt stonework, stiff utilities, or even differentially tight frameworks withstand consistent movement.

Slabs require special care. Residential practice sometimes mounts pieces straight along with small boat docks. On business slabs supporting racks or assembly-line production, I definitely prefer cutting in grade shafts or even mounting under-slab stack hats to accumulate tons. Pieces by themselves have a tendency to rebound and break under aspect mounting. When slab jacking is actually inescapable, use additional points at reduced airlift per factor, as well as consider polyurethane injection to fill up voids after architectural lift, not as a main structural fix.

Helical tieback anchors for sidewise stability

When basements bow or even when dirt stress increases after drainage failings, helical tiebacks offer a clean, testable technique to include sidewise resistance. Commercial helical tieback anchor installation usually involves boring at a shallow angle with the wall, evolving helices past the energetic block right into seasoned ground, and then pressuring the support versus an indoor wale or even outside plate.

Key selections feature the anchor angle, coil setup, and connect length past the breakdown airplane. Proof screening matters extra listed here than just about anywhere because strain creep tells you exactly what you possess. For historical brick or unreinforced masonry, our company prevent aspect tons on the wall through incorporating continual wales or even through dispersing reaction along with steel frames. In waterfront functions, deterioration information rival structural ones; specify double rust defense if service life intendeds surpass a couple of years in chloride environments.

Managing rust and also durability

Deep foundation repair is usually conducted on maturing structures that still possess decades to provide. That suggests deterioration layout is not an explanation. Helical piles and anchors can be found in plain and also galvanized versions. Priming includes quick protection; propitiatory density calculations include lasting self-confidence; in aggressive soils along with low resistivity or even high sulfates, take into consideration epoxy coatings or cathodic defense. Resistance heaps are actually generally steel water pipes or even tube portions; we spec oxidation allowances and, where needed, full of concrete grout to decrease indoor rust and also increase stiffness.

Micropiles provide a baked-in conveniences: a grout cover around steel delivers alkaline protection. Double oxidation defense, benefits of helical piles with central legal professions framed in grout within a corrugated coat or casing, is common in DOT method for high-duty cycles. For business job near utilities or in deicing-salt massive locations, swiping those DOT particulars is actually funds well spent.

Permitting, testing criteria, and information that take on scrutiny

Authorities possessing jurisdiction try to find familiar requirements. For helical piles and anchors, ICC-ES files and AC358 approval requirements overview layout and QA, and also a lot of suppliers post ESRs that connect torque to capability within specified limitations. For micropiles, FHWA guidelines and also PTI recommendations use connect worths, screening methods, and also style systems. Resistance heaps are actually much less standard across suppliers, which puts the onus on developers and also installers to document jacking tensions, airlift, and also segment particulars with clarity.

On large ventures, a third-party special inspector incorporates credibility. Our experts usually provide a package deal that consists of stack logs, exam results, as-builts along with coordinates as well as altitudes, weld and bolt qualifications, grout mix tickets, as well as gradation certificates for twist clues and jacks. When questions happen years later on, this file answers them without guesswork.

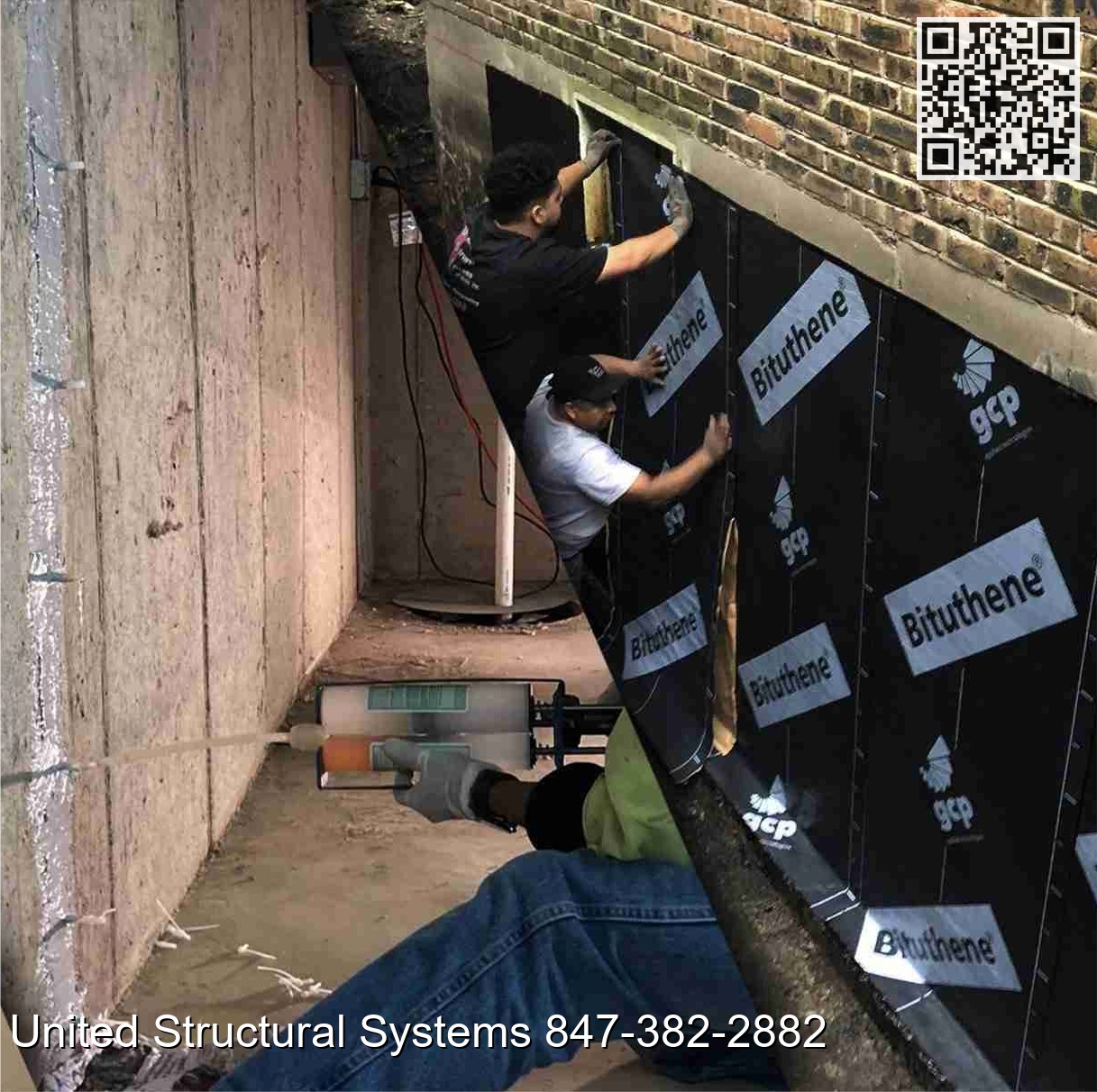

Integrating fracture fixing and basement waterproofing along with architectural work

Owners often request foundation crack repair in the same breathing as deep structure job. Epoxy shot can easily stitch structural cracks after load paths are brought back, while polyurethane treatment or even hydrophilic waterstops deal with leak. Pattern concerns. Support first with commercial foundation stabilization procedures, lift if appropriate, after that infuse. If you inject a relocating fracture, you will certainly go after leaks forever.

Exterior drainage still matters. A row of excellent stacks will definitely not always keep a wall surface completely dry if roofing system forerunners ditch water at the base. We combine swales, downspout expansions, or even border drains pipes where required and, on vulnerable interiors, a negative-side finish or internal drainpipe tile to ease hydrostatic pressure.

Pricing and also booking realities

Unit costs differ by region, manufacturer, and also extent, so any amounts need to be handled as assortments, certainly not quotes. In a lot of markets:

- Helical heaps for industrial usage typically fall in the ball park of moderate 4 amounts per stack mounted at traditional sizes, with torque monitoring and conventional scalps. Tension-rated anchors and tiebacks are identical on a per-capacity basis. Resistance pile expenses rely intensely on intensity to end bearing as well as brace complication. Where bearing is superficial and also the framework is actually hefty, they contend effectively. Where bearing is deep, micropiles or helicals might hammer all of them on creation rates. Micropiles include much higher mobilization as well as component prices per piece, but one micropile can easily replace many much smaller aspects when capability is actually high, specifically with rock sockets or long connect zones.

Schedule hinges on accessibility and also testing. A six-pile underpinning at a singular ground might take a couple of days featuring excavation, setup, lift, and also backfill. A hundred-pile venture can easily operate numerous weeks with overlapping workers. Micropiles demand treatment time for grout before total tons screening or even cap pours, typically 2 to 7 days depending on mix and temperature.

A quick industry instance: 3 systems on one campus

On a college laboratory property, our experts faced three specific troubles. The south segment had actually cleared up 0.9 ins after a nearby energy trench modified water drainage. The cellar wall surface on the eastern side presented sidewise motion and also fracturing. A brand-new rooftop mechanical device demanded two new interior columns carrying uplift throughout wind events.

We utilized resistance stacks under the south wing quality beams. The structure supplied sufficient response for jacking to over 50 kips every pile, and we attained a 0.6 in uniform airlift across nine locations over pair of times. For the eastern wall, commercial helical tieback anchor installation handled the sidewise issue. We punched with slim passages, verification examined each anchor to 1.5 times layout, as well as latched off at company. For the internal columns, commercial helical pile installation delivered both squeezing as well as uplift ability in a tough ceiling height, with round-shaft helicals to avoid twisting in soft clay. The end result: 3 different systems, one use, and a solitary as-built record that the facilities team may reference.

Where to begin on your project

If you deal with or even own an office property with resolution, pitching wall structures, or organized architectural adjustments, the most effective following measure is certainly not picking an item. It is actually scoping an inspection that incorporates a concentrated geotechnical appeal with a functional constructability evaluation. Ask for shear strength accounts, groundwater observations, as well as any corrosivity information. Walk the website along with an installer that has business experience, not merely household job, as well as talk by means of accessibility, staging, as well as exactly how renters are going to be affected.

From there, opt for in between helical piles, resistance stacks, or micropiles based upon ground, tons, gain access to, and also the need for stress, lift, or sidewise capacity. Dedicate to industry confirmation with verification tests and crystal clear documents. Fold up in foundation crack repair only after stablizing. And also keep in mind that commercial foundation repair is successful when the ground truth, structural details, and installation discipline line up.

Deep foundation repair service is actually certainly not glamorous, but when carried out right it goes away in to the framework and gets no attention for the upcoming half-century. That is the goal.