The use of activated carbon for decolorization in the sugar industry to produce white sugar is a commonly used, with the main purpose of removing unwanted substances such as brown pigments, phenolic acids, polyphenols, etc. from the syrup, making the white sugar purer and whiter, with a better taste, and more popular.

1.Traditional sugar decolorization method

The traditional sugar making process is to use chemical clarifiers (such as ash addition method, sulfurous acid method) to turn the non-sugar components in sucrose into precipitates as much as possible or use precipitation to adsorb and remove them. This traditional craft has always been favored by major domestic manufacturers. However, this process is long and the operation is cumbersome. At the same time, new non-sugar components will be added to the sugar liquid, which will have varying degrees of impact on product quality and waste honey output.

Activated carbon adsorption breaks out of the scope of chemical clarification and uses physical or physicochemical methods instead, which can effectively purify sugar liquid and its decolorization range is wider.

2.The decolorization principle of activated carbon on syrup

The activated carbon particles have numerous micro pores interconnected vertically and horizontally, with pore sizes ranging from a few angstroms to a few micrometers. Especially, there are many micropores ranging from a few angstroms to tens of angstroms, and they have corresponding microporous surface areas, which makes their specific surface area very large.

A 1g active carbon with good activity can have a specific surface area of about 1000m2. Due to the fact that the atomic force field on the surface of activated carbon is unsaturated and has residual valence, its surface energy is quite observable at such a large specific surface area. It is precisely because of adsorption that the unsaturated force field on the surface of activated carbon is compensated to some extent, thereby reducing the surface energy. Therefore, at a certain temperature and pressure, the surface of activated carbon can automatically adsorb substances that can reduce its surface energy.

However, the ratio of the quantity of different substances adsorbed by activated carbon from the solution to the concentration of these substances in the solution is inconsistent, as it always strives to equalize the concentration of each solute on the adsorption surface. In this way, even under the same adsorption force, non-sugar components with lower concentrations in the sugar solution are more easily adsorbed than sucrose components with higher concentrations.

The colored substances in the syrup generally have larger molecules and corresponding molecular weights. Through adsorption, the surface energy of the activated carbon can be reduced to a greater extent, so the syrup treated with activated carbon is largely decolorized. It is precisely due to the decolorization and purification effects of activated carbon on syrup that it has been well applied in the advanced sugar industry in many countries.

The advantage of using activated carbon for syrup decolorization is that it does not affect the chemical properties and taste of sucrose, and its impact on the environment is also very small. Therefore, this method is widely used in the sugar industry to ensure the quality, purity, and reliability of sugar products.

Usually there are two styles of using activated carbon to decolorize sugar in sugar industry, batch style and column style.

2.1Batch style

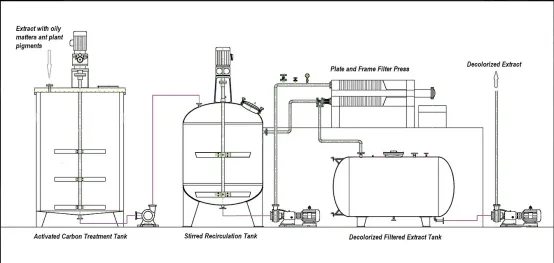

Powder activated carbon type is chosen in this style, there will be a pool or tank in the sugar process flow, after the syrup flows through the pipeline into the pool or tank, activated carbon powder would be added into the pool and stirred with the syrup, during this time, the syrup would be decolorized, activated carbon adsorbs impurities such as phenolic acids and brown pigments, making the syrup clearer.

For this style, ACC WP-1000 wood based activated carbon powder is perfect used in syrup decolorization in this style, this type of powder activated carbon is made of high-quality wood by phosphoric acid activation, contains much lower heavy metal substances compared with coal based activated carbon powder. It can be applied for the purification and treatment of all forms of sweeteners, including corn syrup, sucrose, glucose and fructose syrup etc.

WP-1000 can be added to the raw liquor, held in suspension for some time (contact or residence time) and then filtered using standard techniques. This mode of operation also permits the blending of the activated carbon with other materials such as bleaching earth (common in edible oil treatment).

With Iodine Number: 1000-1300mg/g min. and methylene Blue: 16-22 mL/0.1g, it has well developed micropores and mesopores at the same time, which shows perfect purification and decolorization performance of syrups, it’s widely used in Asian and European countries, like Korean, Japan, Italy, France etc.

In addition, WP-1000 is also widely used in decolorization, purification, deodorization, and impurity removal of high pigment solutions in various amino acid industries, monosodium glutamate industries, glucose industries, starch sugar industries, chemical additives, dye intermediates, food additives, pharmaceutical preparations, etc.

2.2Adsorption bed style

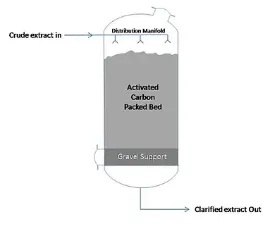

Granule carbon is filled inside the adsorption bed, syrup liquid would pass through it, the adsorption tower could be operated continuously, the granule activated carbon could be recycled through regeneration, it’s more suitable for large-scale production.

The devices mainly come in two forms: fixed bed type and moving bed type. The fixed bed type is the most widely used method. It is easy for manufacturers to operate and maintain. It can improve efficiency through multi-tower operation. The moving bed type has two moving modes: upward and downward. The sugar liquid processed in this way is of uniform quality and can reduce enterprise production costs, without the need for slurry tanks and filter presses, which can reduce the area of the production workshop and make the operation cleaner.

ACC CG-950 MB2 granule activated carbon is specially applied for the treatment and purification of water and all forms of sweeteners in food industry. It can be used for the removal of color and other unwanted byproducts in certain environment.

CG-950 MB2 is a high-performance activated carbon selected high-grade bituminous coal as raw material, after acid wash, advanced and strict production processes, it highly decreases its ash content and adjust its PH value. Finally it becomes an adsorbent with ideal pore structure characteristics and high purity, and its adsorption kinetics has reached an optimal state. Its high-density physical characteristics make this product have an extremely high activity value per unit volume, and can give the product excellent wear value performance, minimizing the loss rate of the product during regeneration and transportation.

Judging from the application results of the customer's factory, CG-950 MB2 shows extremely high decolorization efficiency whether it is used in a fixed bed adsorption devices or moving bed devices.

Compared with powder carbon, granular carbon has a higher loading capacity, which can reduce the use of activated carbon by 30%, and reduce the loss of sugar. In addition to decolorization, it can also absorb odors and is conducive to the use of activated carbon pyrolysis and recycling, reducing carbon emissions by more than five times.

It is worth emphasizing that WP-1000 and CG-950 MB2 are both in neutral pH, 5-8 and 6-8. the reason is during the manufacturing process, because of different activated carbon processing techniques, the final activated carbon product may be acidic or acidic. alkaline. For the sugar making, under acidic conditions, sucrose is prone to conversion, and under alkaline conditions, sucrose is prone to reduction reactions, which is detrimental to the entire sugar making process. So the best PH is in neutral.